Faster Decisions. Fewer Delays. Greater project certainty.

Bringing Clarity, Efficiency and Control to the Construction Industry

Who We Are, Where We Came From, and Where We’re Headed

Introducing EdgeXR, revolutionizing the construction industry with cutting-edge technology. EdgeXR brings virtual reality and augmented reality capabilities to the construction site, making the construction process smoother and more efficient. With EdgeXR, the fragmented and compartmentalized operations in construction are a relic of the past.

Construction documentation and data is transformed into a comprehensive digital twin of the building, effectively eliminating the need for a bulky paper trail. Our as-built digital twin of the building is not just a blueprint but an asset management system for maintenance and operations. Say goodbye to your construction projects’ costly and time-consuming issues of Clashes, Errors, and Omissions (CE&Os). Welcome to the future of construction with EdgeXR and its innovative digital twin technology.

Our company brings 2D blueprints to life through a rich 360-degree virtual reality experience. Models can be visualized by the Microsoft HoloLens or Oculus. The 360 degrees virtual reality service provision causes clients to experience a reduced cost plan as compared to traditional methodologies.

Digitize

Creating critical vectors for dimensional accuracy - Drawing detail creation

Model

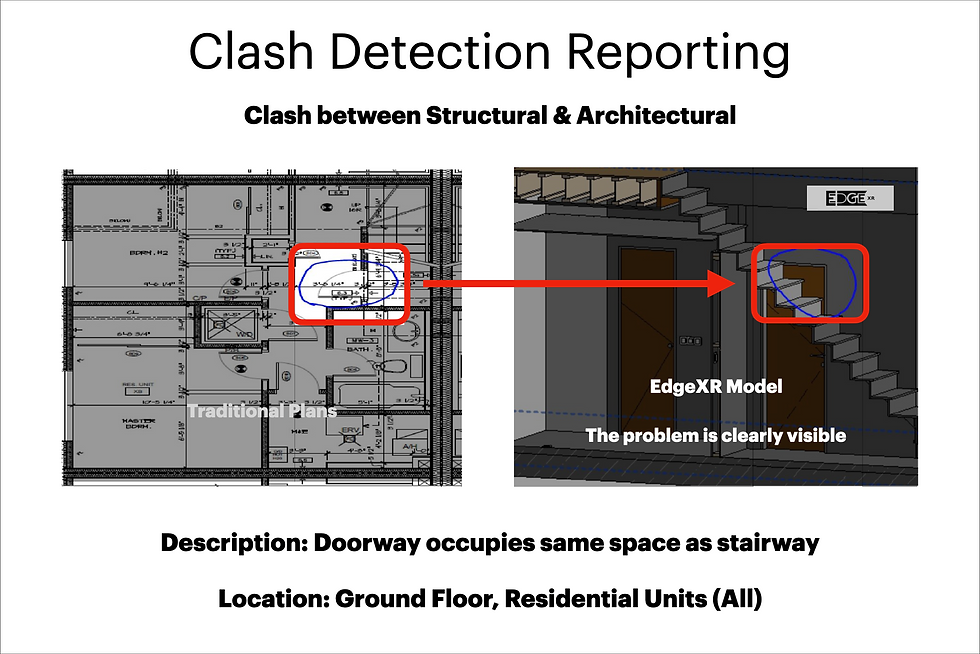

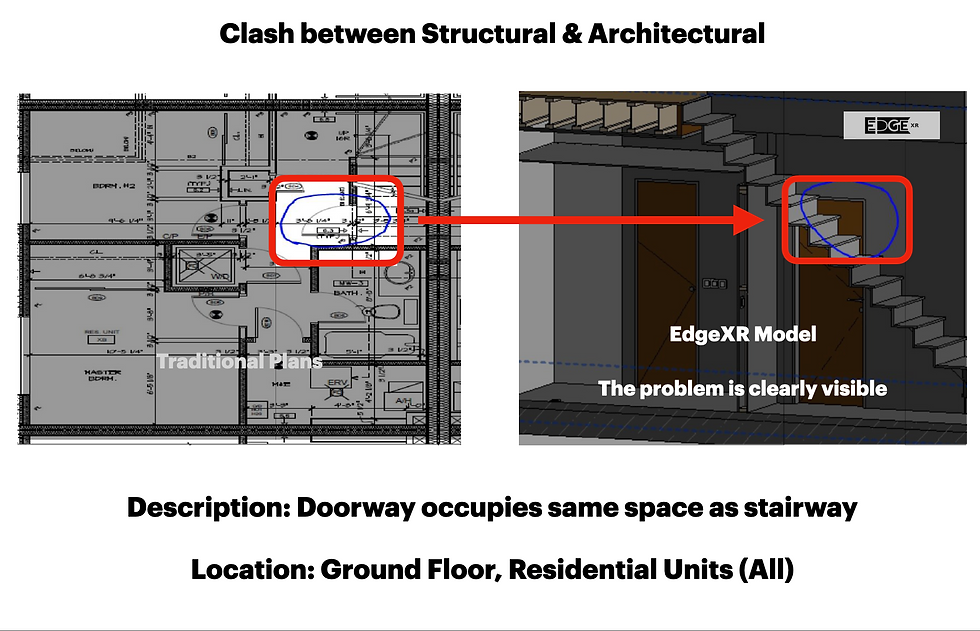

Structural member clash detection, Architectural integration, Assemblies, Interior Finishes, Exterior Finishes, M.E.P

Library Creation

Creating a central library of all digital assets that will be required based on goals of the client

Tracking

Up to date progress tracking and reporting during the building process, live site documentation, tracking, & comparison to central BIM model

Our Features

This is the space to introduce the Features section. Use this space to highlight your unique aspects and to present specific credentials, benefits or special features you offer.

Convert to 3D

Extruding 2D linework into a 3-dimensional asset - Quality Control review by architectsExtruding 2D linework into a 3-dimensional asset - Quality Control review by architects

Assessment

Share your feature information here to attract new clients. Provide a brief summary to help visitors understand the context and background.

Deploy for Build

Onsite Construction - Offsite Modular - Offsite Panelization - Wood & Steel Construction

Setup for Maintenance

BIM LOD 500 - As-Built digital twin for full facilities management

Modern Clash Detection for Modular Construction

This is the space to introduce the Features section. Use this space to highlight your unique aspects and to present specific credentials, benefits or special features you offer.

Factory-specific build instruction

We work on behalf of Investors, Developers, and Project Owners to create a Digital Twin (DTwin) of buildings. We gather all construction documentation and data from architects, engineers, GCs, subs, and suppliers to create a comprehensive and integrated DTwin. This DTwin is a Level of Development (LOD) 500 model of the building, free of CE&Os, that provides accurate and up-to-date information to all stakeholders. We manage the Clash Resolution Process using VR and cloud coordination capabilities, resulting in a DTwin that is free of CE&Os. We also bring Virtual Reality and Augmented Reality capabilities to the construction site for all stakeholders to use. Finally, we create the as-built DTwin of the building to serve as an Asset Management System for maintenance and operations.

What we do

How we do it

This is the space to introduce the Features section. Use this space to highlight your unique aspects and to present specific credentials, benefits or special features you offer.

Factory-specific build instruction

At ClashVR, we control the infrastructure from start to finish by managing our very own design-to-construction process technology. This creates a system that increases the efficacy of BIM360, minimizing the need for handoffs as the infrastructure was built for us!

This efficacy is brought to headwear or tablets for internal workers, giving them access to approved data directly from engineering and architecture. Doing so increases the availability of all data and assists in relaying updates to all stakeholders live.

What Can We Do Differently? – Structural/MEP

Our capital investment in technologies allow us to automate 40 to 75 percent of our process in framing using AGACAD to our procurement specifications. This framing suite allows us to export to factory trained CNC machines, further automating the construction process. As the model becomes further refined, takeoffs become more accurate.

Introducing EdgeXR, revolutionizing the construction industry with cutting-edge technology. EdgeXR brings virtual reality and augmented reality capabilities to the construction site, making the construction process smoother and more efficient. With EdgeXR, the fragmented and compartmentalized operations in construction are a relic of the past. Construction documentation and data is transformed into a comprehensive digital twin of the building, effectively eliminating the need for a bulky paper trail. Our as-built digital twin of the building is not just a blueprint but an asset management system for maintenance and operations. Say goodbye to your construction projects’ costly and time-consuming issues of Clashes, Errors, and Omissions (CE&Os). Welcome to the future of construction with EdgeXR and its innovative digital twin technology.

Modern Clash Detection for Modular Construction

We work on behalf of Investors, Developers, and Project Owners to create a Digital Twin (DTwin) of buildings. We gather all construction documentation and data from architects, engineers, GCs, subs, and suppliers to create a comprehensive and integrated DTwin. This DTwin is a Level of Development (LOD) 500 model of the building, free of CE&Os, that provides accurate and up-to-date information to all stakeholders. We manage the Clash Resolution Process using VR and cloud coordination capabilities, resulting in a DTwin that is free of CE&Os. We also bring Virtual Reality and Augmented Reality capabilities to the construction site for all stakeholders to use. Finally, we create the as-built DTwin of the building to serve as an Asset Management System for maintenance and operations.

Modern Clash Detection for Modular Construction

Digitize

Creating critical vectors for dimensional accuracy - Drawing detail creation

Convert to 3D

Extruding 2D linework into a 3-dimensional asset - Quality Control review by architects

Model

Structural member clash detection, Architectural integration, Assemblies, Interior Finishes, Exterior Finishes, M.E.P

Assessment

Clash detection, Subtrade inspection, Architectural review, Cost analysis, Heat loss model, Solar gain model

Library Creation

Creating a central library of all digital assets that will be required based on goals of the client.

Deploy for Build

- Onsite Construction - Offsite Modular - Offsite Panelization - Wood & Steel Construction

Tracking

Up to date progress tracking and reporting during the building process, live site documentation, tracking, & comparison to central BIM model

Setup for Maintenance

BIM LOD 500 - As-Built digital twin for full facilities management

How We Do It

High Value Engineering

At ClashVR, we control the infrastructure from start to finish by managing our very own design-to-construction process technology. This creates a system that increases the efficacy of BIM360, minimizing the need for handoffs as the infrastructure was built for us!

This efficacy is brought to headwear or tablets for internal workers, giving them access to approved data directly from engineering and architecture. Doing so increases the availability of all data and assists in relaying updates to all stakeholders live.

What Can We Do Differently? – Structural/MEP

Our capital investment in technologies allow us to automate 40 to 75 percent of our process in framing using AGACAD to our procurement specifications. This framing suite allows us to export to factory trained CNC machines, further automating the construction process. As the model becomes further refined, takeoffs become more accurate.